Description

LNS-Line Precision Shell & Tube Heat Exchangers

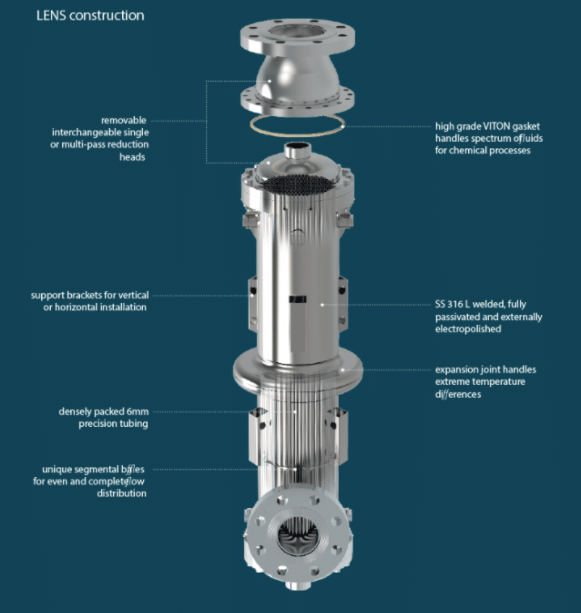

A collaboration of practicality, versatility, durability, and a dash of novelty, the LENS heat exchangers break the mold with a new multi-functional, multi-dimensional, transformative ingenuity opening doors to unprecedented possibilities in fluid dynamics and process control.

The strength of the LENS series lies in its adaptive nature, allowing customization of standard products to optimize its effectiveness in varying applications. From hydronic heating to steam condensers, and all processes in between, the LENS offers clients unrivaled quality with the highest degree of flexibility.

Applications

- Steam condensers (flooded heat exchangers)

- Oil coolers

- Gas Coolers

- Chilled water systems

- Process cooling

- District energy

- Hydronic heating and cooling

Standard Materials

- Stainless Steel 316L

Maximum Working Pressure

- Up to 150 PSI (10 bar) in Tubes

- Up to 300 PSI (21 bar) in Shell

Maximum Working Temperature

- Up to 375°F (190°C) Tube Side

- Up to 422°F (217°C) Shell Side

Effortlessly create a customized heating system using modular LENS components. Whether to optimize a single design, or to construct a multi-sectional, integrated structure, the potential is boundless.

Surpassing conventional heat exchangers with its fresh, inventive design, the LENS heat exchanger system skillfully incorporates in all the ‘must-have’ thermal features valued in the heat recovery market, excelling in all competencies through uncompromising quality and fine craftsmanship.

Advantages

- Dense heat transfer area packed in a compact construction

- High flows with low pressure drops

- Small footprint

- Multiple configurations of removable single or multi-pass heads

- Possibility of large connections for low density vapours

- Close temperature approach and condensate sub-cooling

- Versatile working positions and connection orientation.