Apollo Valves High Performance Butterfly Valves 215/230/260 Series

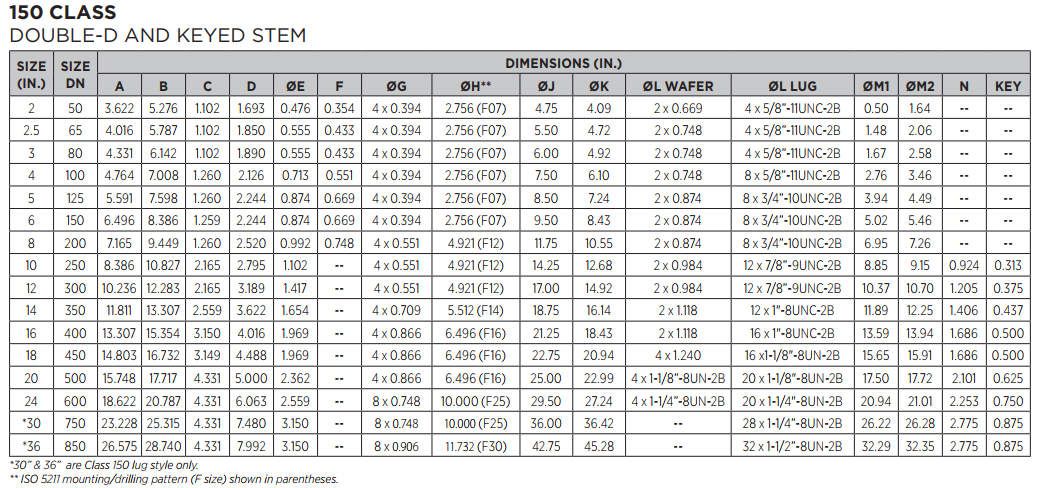

CLASS 150 – 2″ THRU 24″, 30″, 36″ – 215 Series

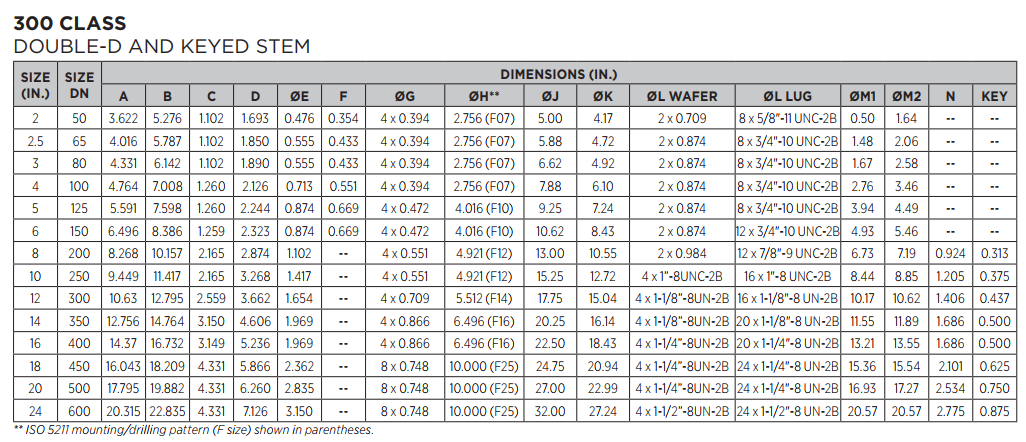

CLASS 300 – 2″ THRU 24″ – 230 Series

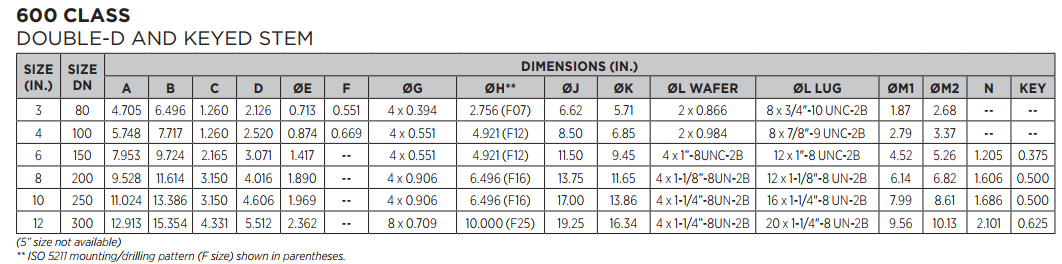

CLASS 600 – 3″ THRU 12″ – 260 Series

STANDARD COMPLIANCE

• ASME B16.10 “Face to Face and End to End Dimensions of Valves”

• ASME B16.34 “Valves – Flanged, Threaded, and Welding End”

• ASME B16.5 “Pipe Flanges and Flanged Fittings”

• ANSI/FCI 70-2 “For Control Valve Seat Leakage”

• MSS SP-25 “Standard Marking System for Valves”

• MSS SP-44 “Steel Pipe Line Flanges”

• MSS SP-55 “Quality Standards for Steel Castings”

• MSS SP-61 “Pressure Testing of Steel Valves”

• MSS SP-68 “High Pressure Butterfly Valves with Offset Design”

• API 598 American Petroleum Institute – “Valve Inspection and Testing”

• API 607 – 6th Ed. American Petroleum Institute – “Fire Test for Soft Seated Valves”

• API 609 American Petroleum Institute – “Butterfly Valves: Double Flanged, Lug and Wafer Type”

• NSF/ANSI/CAN 61 “Drinking Water System Components – Health Effects” (2” – 24”, Stainless 215 & 230)

• NSF/ANSI 372 “Drinking Water System Components – Lead Content” (2” – 24”, Stainless 215 & 230)

CERTIFICATIONS

• CE Marking and documented valves that conform to the European Pressure Equipment Directive (PED) 97/23/EC are available in ANSI Class

150/300/600 including soft, fire safe and metal seat configurations (sizes 2″-24″ only).

• CRN No. 0C17459.5CL

SERVICES

VACUUM SERVICE

• Standard Apollo high performance butterfly valves are rated for 29” Hg vacuum.

STEAM SERVICE

• The Apollo® high performance butterfly valve is well-suited for a wide range of steam applications. The application range is defined in the high

performance butterfly valve pressure-temperature charts