Description

TRIPLE DUTY VALVES

Model ‘125TDFI’

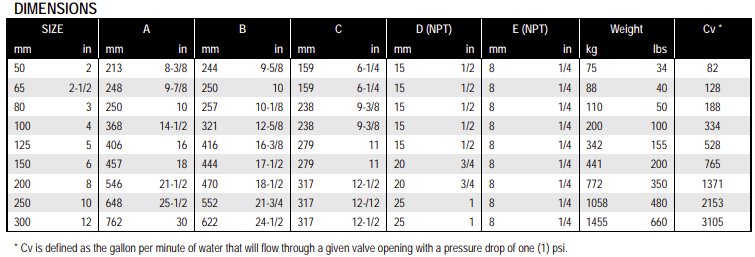

Available in sizes 2″ to 12″ with ANSI 125# FF flanged ends

RATINGS

Maximum Allowable Working Pressure: 200 PSIG @ 150°F

Maximum Allowable Working Temperature:

250°F (EPDM seal)

400°F (Viton seal)

Materials of Construction:

Valve Body: A126-B Cast Iron

Valve Disc: A536 Nickel Plated Ductile Iron

Valve Stem: 410 Stainless Steel

Valve Stem Guide: A536 Ductile Iron

Packing: Non-Asbestos Fiber

Packing Gland: A126-B Cast Iron

Spring: 300 series Stainless Steel

Valve Seat Ring: A536 Nickel Plated Ductile Iron

Valve Seat Seal: EPDM O-Ring (Viton Optional)

Valve Disc Seat: EPDM O-Ring (Viton Optional)

FEATURES

● Acts as three valves in one. On a pump discharge, a triple duty valve replaces the need for a balancing valve, shut-off valve and a check valve

● 125# ANSI flat face flanged ends in accordance with ASME B16.1

● To prevent water hammer, the triple duty valve is spring loaded to ensure that the disc closes as the line flow approaches zero

● 1/4 psi cracking pressure

● The rising stem allows for adjustment from zero to full flow

● EPDM seat seal supplied as standard

● Bubble-tight shut-off

● Valve position indicator

● All sizes supplied with valve hand-wheel operator

● Tapped and plugged drain and differential connections