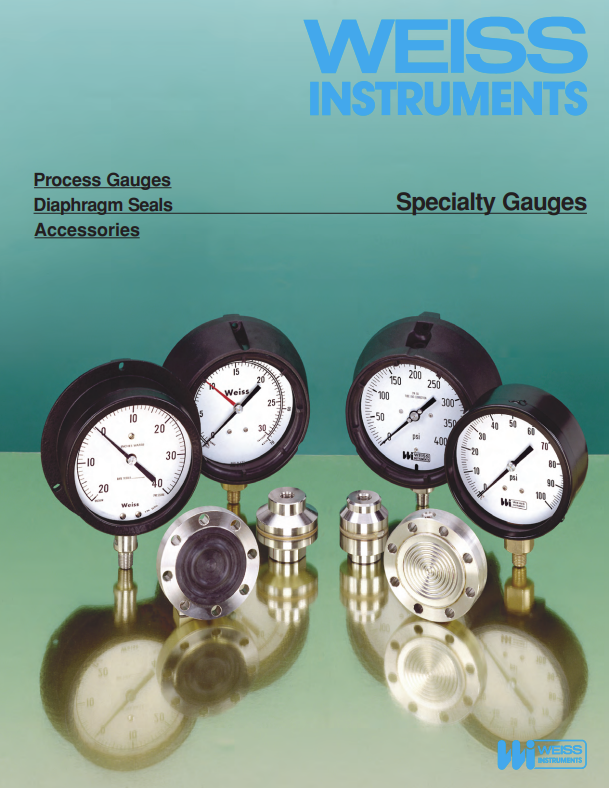

Specialty Gauges

Process Gauges, Diaphragm seals, Accessories

Weiss Instruments Specialty Gauges include various pressure gauges available in Solid Front(Safety), Solid Back Liquid-Filled or Dry configuration. These gauges ideally suit the requirements of the Process, Industrial, Power and Chemical Industries and are available with Phosphor Bronze/Brass, 316Stainless Steel or Monel internals.

Gauge accessories such as: Siphons, Snubbers, Gauge Cocks, Needle Valves, Ball Valves andDiaphragm Seals (to prevent corrosion or clogging of Gauges) are also illustrated.

Operating Conditions

Conditions which a pressure gauge will be subjected to are a major factor in choosing the correct indicator for each application. The following points are offered as a guide for the proper selection.

• Where vibration and pulsation exist, the liqiud-filled type may be better suited.

• Gauge range should be twice that of the operating range. Additional information can be obtained by reading Pressure Gauge Standard ANSI/ASME B40.1.

• Liquid filled ambient temperature limits – Glycerine 0-150°F / Silicone 50-0-150°F

• Non-filled gauges can withstand continuous service temperatures as high as 300°F, however, excess operating temperatures should be avoided when ever possible since mid-scale accuracy will be affected by approximately 1% per 100°F ambient temperature change.

• Non-filled gauges with stainless steel components and welded joints will withstand higher temperatures for short periods of time, although other internals may be damaged and calibration permanently affected.

• For highly corrosive and/or viscous process media a diaphragm seal may be appropriate to isolate the gauge.