Description

FLASH VESSELS

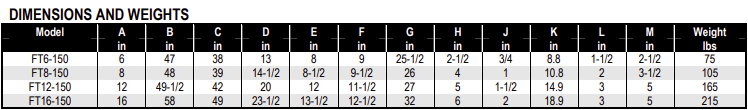

Series ‘FT’ Flash Tanks

PURPOSE

All steam systems produce flash steam which is usually wasted when it escapes through the condensate receiver vent pipe. Boiler blowdown also produces significant amounts of flash steam. The cost of a Flash Steam Recovery System is usually paid back very quickly – almost always in less than one year

NOTES

● Finished with one coat of maroon primer

● Higher pressure ratings are available upon request

● Dimension can be modified to suit specific requirements

DESIGN SPECIFICATIONS

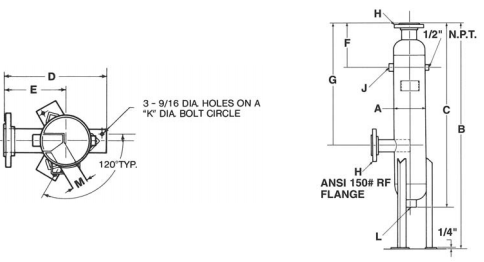

Design Standards: ANSI B16.5

Design Code: ASME Section VIII, Div. 1, latest revision

Design Pressure: 285 psig

Design Temperature: 100°F

M.D.M.T.: -20°F

Hydrostatic Test: 430 psig

Design Steam Pressure: 150 psig saturated

Heat Treatments: None

Service: Non-Lethal

Material of Construction: Carbon Steel per ASME Sect. II (A)

Ordering Information Required:

- Pressure at high pressure steam trap/s or blow down metering valve/s feeding the flash tank.

- Volume of high pressure condensate (usually expressed in lbs/hr.)

- Pressure of the lower pressure system that we will be supplementing.