About Shipco Pumps Company

Shipco® Pumps is a privately held company engaged in the design, development, production, and distribution of a wide range of engineered products grouped into six product groupings. Products are targeted for applications in the steam recovery operations of a boiler steam system. These steam-related products are primarily used, but not limited to public institutions such as hospitals, schools, colleges, universities, prisons, state buildings or military bases; as well as commercial and industrial industries such as automobile, airline, brewery, pharmaceutical, baking or shipping.

Shipco® is one of the few, remaining U.S. manufacturers that both designs pumps, as well as manufactures complete, packaged units. This combination of capabilities enables it:

Shipco Pumps Products

View our Shipco Pumps Products

Condesate Return Pumps

Condensate pumps are designed to collect condensed liquid at remote locations in a steam system and move it back to the boiler room. Condensate can be driven by either electricity or steam. Motor-driven pumps typically have centrifugal type pumps and include controls that de-energize the pump when water level in receiver is low. A typical motor-driven unit consists of a 3/16″ thick, welded steel receiver or cast iron receiver with an industry-standard electric motor that is close coupled to a bronze-fitted, centrifugal pump. Both simplex and duplex configurations are available with/without mounted, pre-wired control panels. The steam-driven units are typically used in hazardous environments or where electricity may not be readily available.

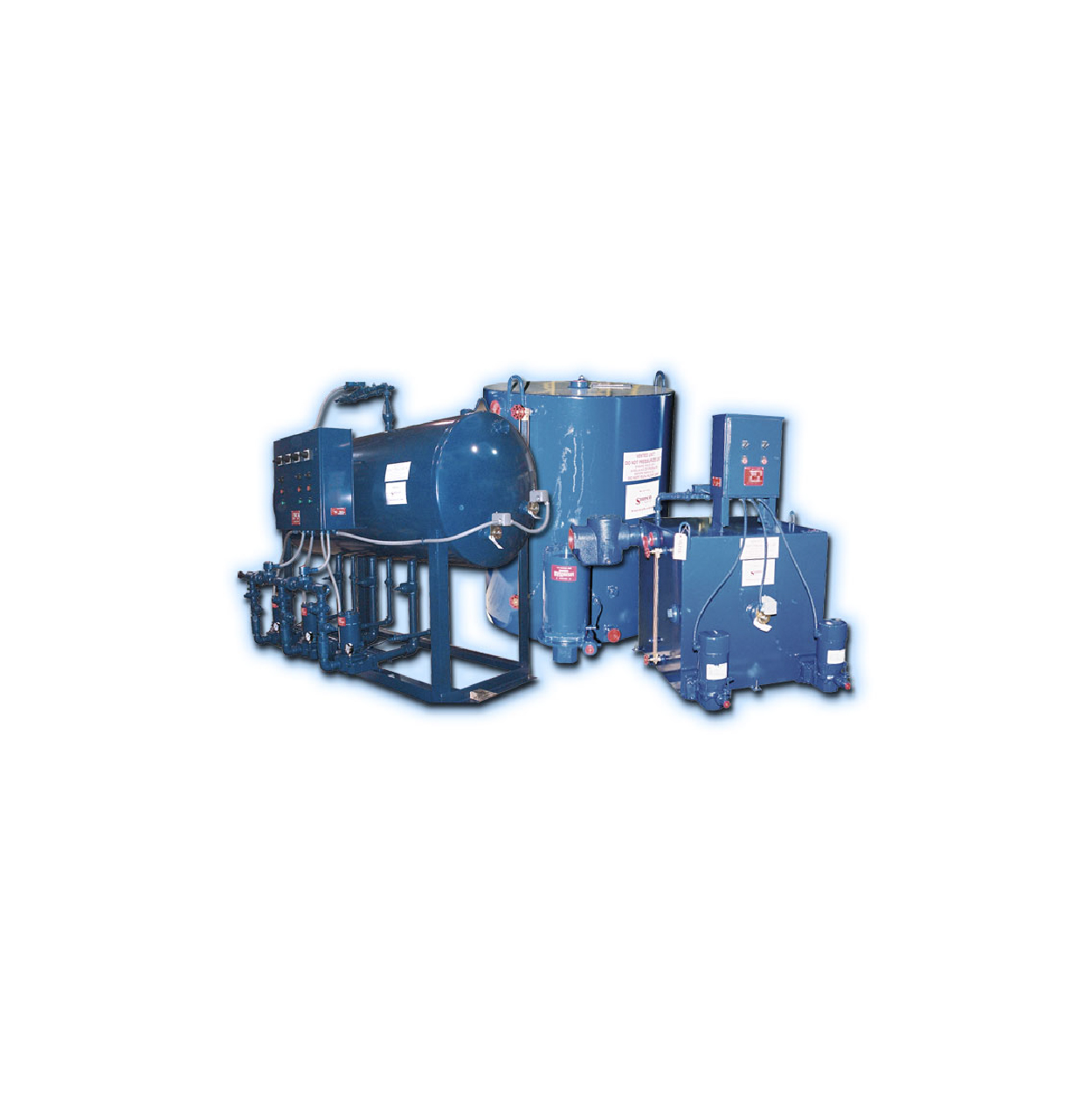

Boiler Feed Pumps & Surge Tanks

Designed to provide feedwater to a boiler. A level controller on the boiler activates the boiler feed pumps. Both atmospheric tanks and pressurized tanks are available with or without a direct injection style heater (sometimes called a preheat tube). Pressurized tanks can be ASME code constructed or ASME code stamped. Tanks material may be cast iron, black steel or stainless steel; black steel tanks maybe epoxy-lined or plasite-lined. A typical package includes the receiver, feed pumps assembled and piped, along with a mounted, pre-wired control panel. Unit can be elevated on steel frame.

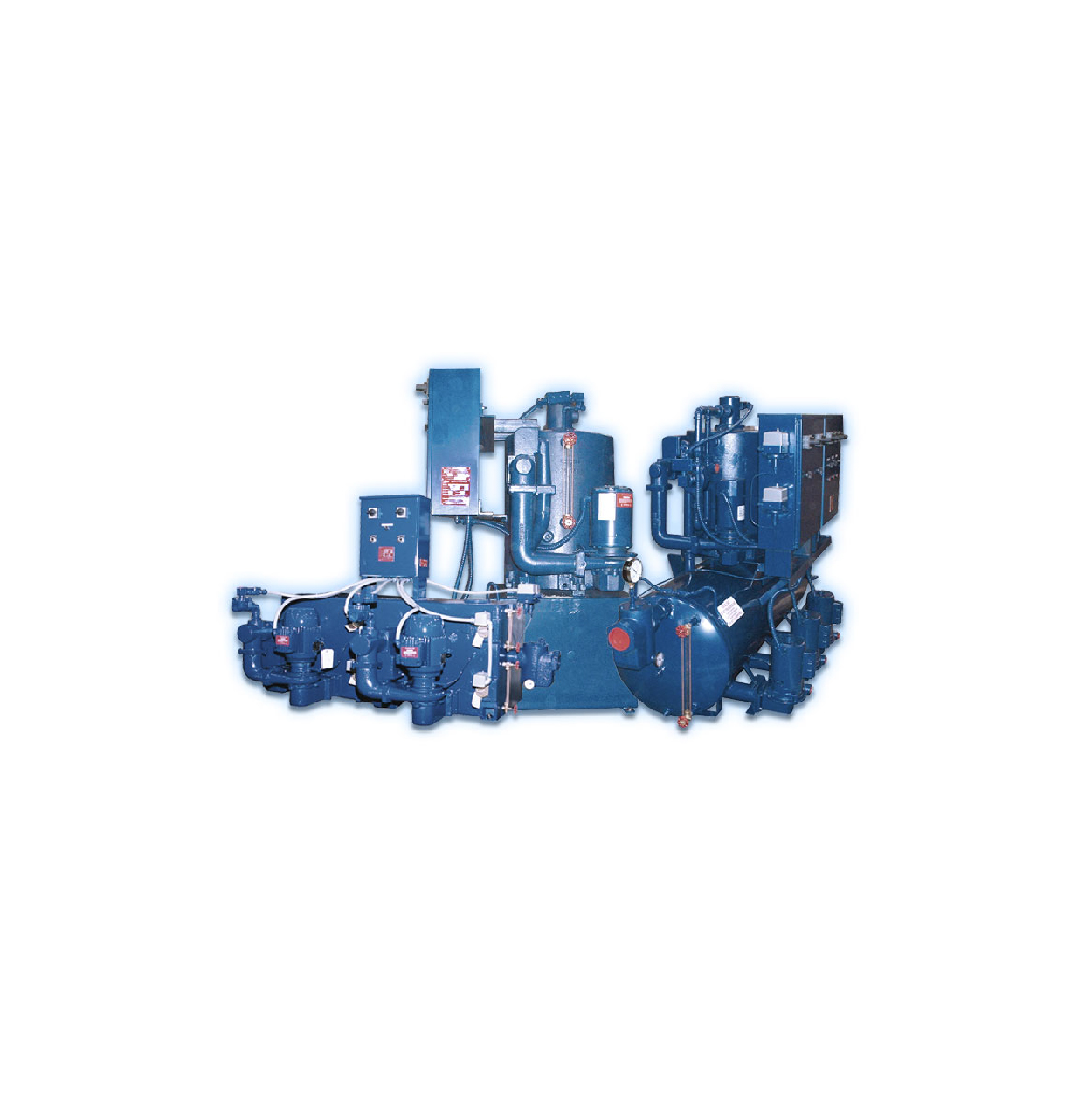

Dearators

The mechanical deaeration process is one of the most economical methods for removing corrosive gases such as dissolved oxygen from boiler feed water. Dissolved oxygen in feed water is the major cause of boiler corrosion. A standard .03 deaerator design removes dissolved oxygen to a maximum level of .03 cubic centimeters per liter of feed water; rating can also be expressed as 44 parts per billion of oxygen in the feed water by weight. A standard .005 deaerator design removes dissolved oxygen to a maximum level of .005 cubic centimeters per liter of feed water; rating can be expressed as 7 parts per billion of oxygen per liter of feed water.

Vacuum Pumps & Producers

Designed to remove air and lift condensate in the condensate recovery portion of your steam heating system. Receiver typically has two compartments—one to collect hot condensate and one to produce the vacuum. Tank material can be close-grained cast iron or black steel. Thicker black steel or 300 series stainless steel is option on some models for increased corrosion resistance. Both simplex and duplex configurations are available with/without mounted, pre-wired control panels.