Description

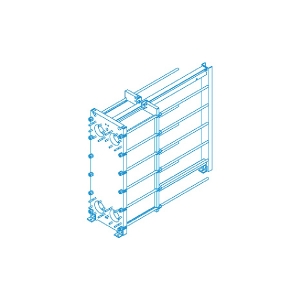

ABX Brazed Plate Heat Exchangers

Applications

- Radiant floors, snow melting, domestic hot water heating, swimming pool heating, heat pumps, heat recovery, district heating, steam condensing, and refrigeration.

Description

-

- The Armstrong ABX plate and frame heat exchangers are suitable for use in any installation involving hot water boilers. The wide range of in stock models assures fast project turnaround.

Materials

-

-

- Plates: stainless steel, nickel alloys, titanium (alloys)

- Gaskets: elastomer materials, sigma coat, compressed fibers (non-asbestos)

-

Performance range

- In-stock selection covers applications from 0.5 USgpm to 160 USgpm. Larger models available for up to 600 USgpm.

Low installed cost

- Superior heat transfer coefficients of Armstrong ABX exchangers allow for substantially smaller build and footprint at equivalent or better performance compared to other heat transfer devices – resulting in significant space savings

- Highly compact design, with all connections being on the same plane, for fast and convenient installation in tight spaces

Superior heat transfer rates and excellent building comfort

- Turbulent-flow design moves the two media in opposite directions and creates strong turbulences for superior heat transfer rates and efficiency

- Highest responsiveness to changes in system demand for superior space conditioning compared to other similar designs

Low operating risk and cost

-

- Brazed-plate and anti-scaling flow design for reduced maintenance cost and longer equipment life

- Brazed-plate design eliminates the need for gaskets (and replacement)