Description

Plate & Frame Heat Exchangers

The Armstrong plate and frame heat exchanger consists of a number of specially corrugated metal plates assembled in a frame and bolted between two pressure plates, one fixed and one adjustable. Turbulence is created in the liquid flow channels, which creates very high heat transfer coefficients and provides efficient heat transfer in a compact design. Armstrong plate and frame heat exchangers are normally supplied with stainless steel plates. Titanium plates are available as an option.

Armstrong plate designs have been optimized for water-to-water heat transfer to provide enhanced performance in HVAC applications. Units are designed for 100 psi, 150 psi and 300 psi (690 kPa, 1034 kPa and 2068 kPa) designs. Applications requiring higher working pressures as high as 400psi (2757kPa) can also be accommodated.

Applications

-

- Central HVAC and ancillary cooling, lube oil coolers (turbines), seal water coolers (vacuum pumps), gearbox oil cooling (wind turbines), ground water isolation exchangers (geothermal)

Description

-

- The Armstrong PFX plate and frame heat exchangers consist of a number of specially corrugated metal plates assembled in a frame and bolted between two pressure plates (one fixed and one adjustable.) Armstrong plate designs are optimized for best water-to-water heat transfer providing enhanced performance especially in HVAC applications.

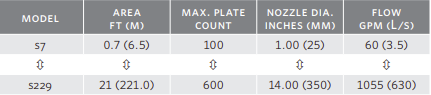

Dimensions

Materials

-

-

- Frames and pressure plates: stainless steel, painted carbon steel

- Bolts: stainless steel, zinc-coated carbon steel

- Support column (optional): stainless steel, painted carbon steel, aluminum

- Plates: stainless steel, nickel alloys, titanium (-alloys)

- Gaskets: elastomer materials, sigma coat, compressed fibers (non-asbestos)

-

Configuration

- Range of different connection types and materials. ASME code construction

Performance range

- Standard models available in three pressure ratings: 100 psi, 150 psi, or 300 psi (690 kPa, 1034 kPa and 2068 kPa)

- Custom designs available for higher pressure requirements

Power Range: N/A

Low installed cost

- Superior heat transfer coefficients of Armstrong PFX exchangers allow for smaller build and footprint at equivalent or better performance compared to other heat transfer devices – resulting in significant space savings

- Highly compact design for fast and convenient installation in tight spaces

Superior heat transfer rates and excellent building comfort

- Turbulent-flow design moves the two media in opposite directions and creates strong turbulences for superior heat transfer rates and efficiency

- Highest responsiveness to changes in system demand for superior space conditioning compared to other similar designs

Low operating risk and cost

- Expandable design for cost effective adaptation to changing overall heating or cooling demands