Description

Shell & Tube Heat Exchangers

High security against cross-contamination

Type W, WS, WR and U-Tube

Armstrong U-Tube heat exchangers are designed for durability and include a removable tube bundle as a standard feature. The U-shaped tube design provides a long service life by eliminating the effects of thermal expansion and contraction. These heat exchangers feature carbon steel components, 0.75” (19 mm) copper tubes, and a rugged cast iron head. Components are also available in a selection of materials for use in specific applications

Type WX, WSX, WRX Double-Wall and U-tube

Double-Wall tube (tube-in-tube design) heat exchangers are designed for applications where it is critical that the system prevents the mixing of internal fluids, i.e. potable water heaters. These units, in the event of a leak, allow the liquid to drain to atmosphere. Made from the same quality components as the W Series, the tube bundle from a WX Series heat exchanger will fit the shell of an existing W Series heat exchanger

- Double-wall, tube-in-tube construction channels potential leakage due to corrosion or abrasive action to the outside of the unit. Thus leaks can be detected before contamination of either fluid in the heat exchanger can occur

Applications

-

- Broad range of commercial and industrial applications where fluids must be quickly heated or cooled.

Description

-

- The Armstrong Shell & Tube heat exchangers provide dependable, efficient heat transfer in various applications ranging from HVAC to industrial installations. Armstrong Shell & Tube heat exchangers are suitable for higher-pressure applications in oil refineries and other large chemical processes.

Materials

-

- Standard Copper (tubes), carbon steel (shell, tube sheet, baffles) Optional Brass (tubes, tube sheets, baffles), bronze (heads), stainless steel (tubes, tube sheets, heads, shells, baffles), 90/10 Cu-Ni (tubes)

Configuration

- Single wall-tube or double wall-tube designs. Optional high-pressure designs. Custom designs available in special materials

Features

• Carbon steel shell, tubesheet and baffles

• Heavy-duty U-shaped copper tubes

• 2 and 4-pass construction

• Constructed in accordance with asme Boiler Code Section viii, Division 1

• 4” to 30” (102 mm to 762 mm) diameter in varying lengths

• WS – water in tubes, steam in shell

• WR – steam in tubes, fluid in shell

• W – fluid in tubes and shell

Options Available

• Carbon steel, brass, stainless steel or 90/10 Cu-Ni tubes

• Flanged heads with pressure rating of 150 psi (1034 kPa)

• Bronze or stainless steel heads

• 316 stainless steel shell

• Brass and 316 stainless steel tubesheets

• Brass and 316 stainless steel baffles

• Double-wall tubing with double tubesheet

• High pressure 300 psi and 400 psi (2068 kPa and 2758 kPa) designs

• Custom sizes and construction

• Carbon steel saddles

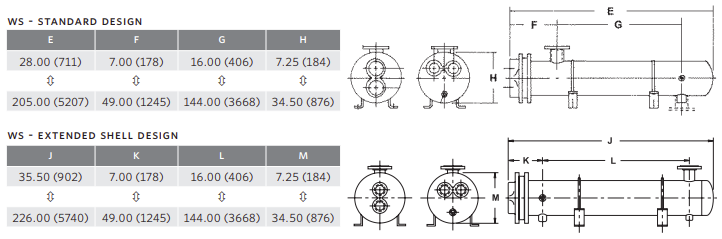

Dimensions

Easy and efficient heat exchanger upgrades

- Thermal performance of an Armstrong double-wall heat exchanger is equal to a conventional single-tube unit of similar size and square foot surface area

Easy tube bundle replacement and maintenance in existing installations

- Replacement tube bundles are easy to install and can be adapted to fit most other U-bend heat exchangers